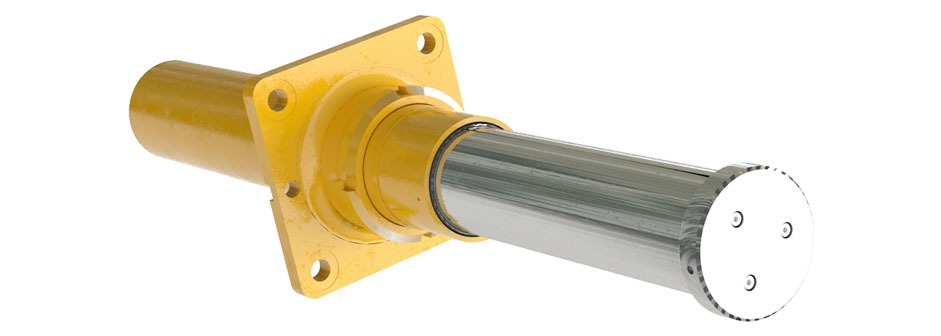

HYBUFF G-series buffers

Our more standardised HYBUFF G-series buffers (where G stands for gas hydraulic buffers) have been developed to give you cost effective solutions for your energy absorption needs and can replace the most common brand on a ‘plug and play’ basis. They are ideal for applications where an energy stop device is needed and they have a robust design that offers strong resistance for higher forces.

How do they work?

The buffers have a cylinder filled with oil and a hollow piston rod. The piston rod contains the reservoir and a floating piston which separates oil and gas. The damping force is then achieved by a metering pin in the middle of the buffer that regulates the flow area, restricting it when the buffer is compressed.

Our standard range

Type 63

Fmax 200 kN

Stroke lengths 50–400 mm

Type 80

Fmax 300 kN

Stroke lengths 50–600 mm

Type 90

Fmax 500 kN

Stroke lengths 100–800 mm

Type 120

Fmax 700 kN

Stroke lengths 200–600 mm

Type 220

Fmax 700 kN

Stroke lengths 800–1,200 mm

A high spec as standard

The HYBUFF G-series buffers come with optimum corrosion protection included as standard − right up to ISO EN 12944 C5M, which is tough enough for harsh sea environments. The buffers also have an Ni-compound treated plunger, a stainless steel end cap and a front or back mount as standard. And, for the ultimate finishing touch, you can choose any colour paint for the cylinder – just give us your RAL number or Pantone reference!

There are then two optional extras available, namely a bellow and a safety chain.